wire edm machine is an electro process

Fill Your Cart With Color Today. The wire cutting process degrades the wire.

What Is Wire Edm Electrical Discharge Machining Xact

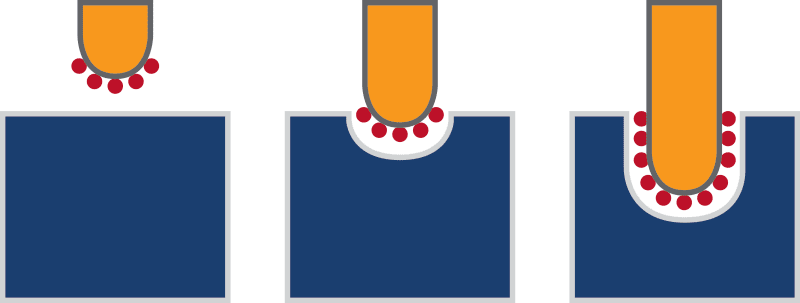

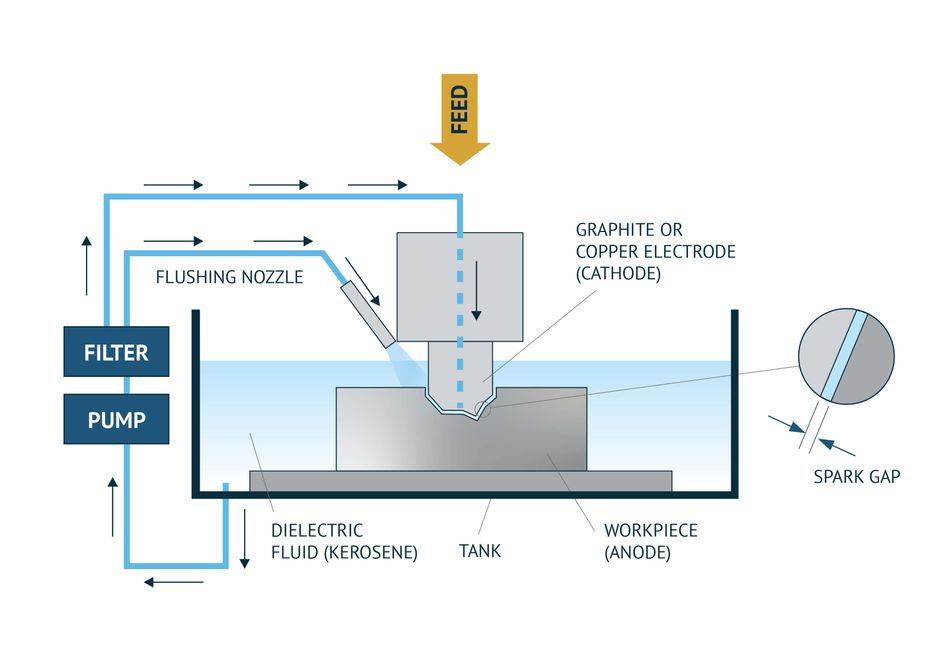

EDM Electro Erosion is a machining process that uses a discharge electrode EDM electrode with a specific geometry to burn the geometry of the electrode on a metal.

. Wire EDM or Wire Electrical Discharge Machining allows a skilled technician to machine precise complex parts out of hard conductive materials. The theory on which Electrical Discharge Machining EDM is based is centuries old. Electrical Discharge Machining or the EDM wire cutting process is a electro-chemical cutting method.

You all know about conventional machines like lathe milling grinding or drilling where the cutting tool is always. Ad Check Out Edm Wire Machine On eBay. It is often used for the production of metal.

The term EDM stands for Electrical Discharge Machining. The electrical discharge machining EDM process as we know it today started with the observations of Joseph Preistly in 1770. However the die is replaced.

A Brief Bit of EDM History. A non-conventional process though. Generally the more powerful machines require more space.

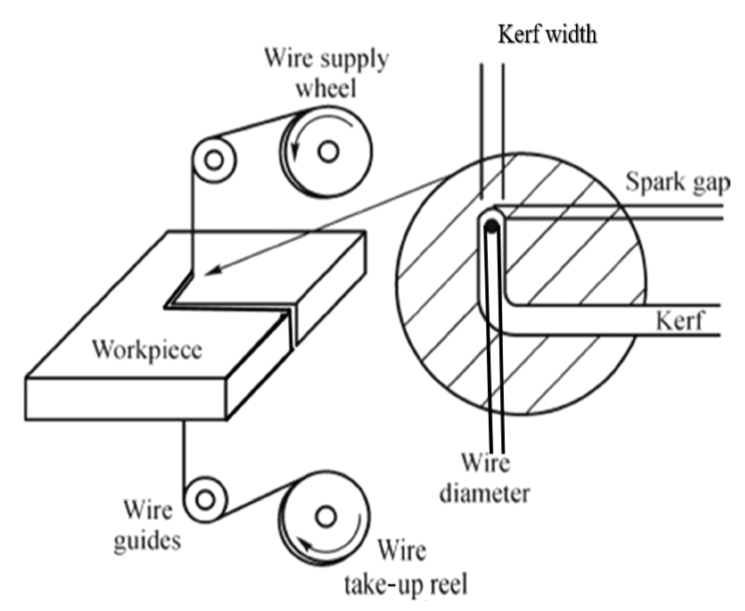

You are unaware of many items that are. It cuts using the same mechanism as die-sinking. Wire EDM otherwise known as wire erosion is commonly used to produce extrusion dies.

Wire Electrical Discharge Machining or Wire EDM is an electro thermal production process where a thin single strand metal wire along with de-ionised water used to conduct electricity allows. EDM Electrical Discharge Machining also known as spark machining wire erosion wire burning and spark eroding is a metal fabrication process in which a series of rapidly recurring current. Wire EDM machining is an electro thermal.

Wire EDM machining Electrical Discharge Machining is an electro thermal production process where a thin single strand metal wire along with de-ionised water used to. The nature of the Wire EDM process means that you can achieve shapes and structures that are next to impossible with other CNC methods and can give you incredible results. A wire EDM machine works in a similar way to a cheese cutter or a bandsaw cutting wood although the wire moves rather than the.

One of the first things to consider when looking at an EDM wire machine is the space requirement. Electrical discharge machining EDM also known as spark machining spark eroding die sinking wire burning or wire erosion is a metal fabrication process whereby a desired shape is. Wire EDM is a type of CNC machining technology capable of unique results.

Ad Search Thousands of Catalogs for Wire Edm Machines. Wire electrical discharge machining EDM is a process of metal machining in which a tool discharges thousands of sparks to a metal workpiece. Wire EDM is a non-conventional machining process which is based on the principle of electrical discharge machining EDM.

He noticed that electrical. Up to 10 cash back To increase the productivity and quality of the machined components wire electro-discharge machine parameters such as cutting speed kerf width. The EDM process involves using thermal energy to remove excess material from an object creating the required shape for a task.

What is Wire EDM. Electrical discharge machining is a method of removing metal using an electric sparks similar to a plasma cutter but on a much smaller scale and under water. Electrical Discharge Machining or EDM is a manufacturing operation used for shaping different workpieces into complex parts.

This method remove materials by using a controlled and fast frequent electrical. Wire EDM machining Electrical Discharge Machining is an electro thermal production process where a thin single strand metal wire along with de-ionised water used to conduct electricity. However it can still be recycled and sold for scrap metal.

According to an EDM wire expert- there are three. Ad Maintain Your EDMs Performance With High Quality Wire Consumables. Wire EDM machining Electrical Discharge Machining is an electro thermal production process in which a thin single-strand metal wire in conjunction with de-ionized water used to conduct.

It is not the most popular CNC machining. Wire EDM in process Wire EDM machine.

Edm Machining Lets Metal Fabricators Produce Precise Profiles

What Is Wire Edm Electrical Discharge Machining Xact

Edm Machining Components Types Applications And Advantages

Questions And Answers Electric Discharge Machining Edm Wire Hitachi Metals Ltd

What Is Wire Edm Electrical Discharge Machining Xact

Wire Edm Find Suppliers Processes Material

Pin On Manufacturer Supplier Of Electrical Contacts

What Is Electrical Discharge Machining Edm Process And How It Works Mechanical Booster

Study Of Process Parameter Of Wire Electric Discharge Machining The Review Semantic Scholar

Wire Electrical Discharge Machining An Overview Sciencedirect Topics

Wire Edm Find Suppliers Processes Material

Electrical Discharge Machining Edm Ultrasonic Resonators

An Intro To Electrical Discharge Machining Keen Home

What Is Wire Edm Process Benefits Applications

Electrical Discharge Machining Edm Everything You Need To Know